Blue Spirulina is a natural blue pigment-protein extracted from spirulina, valued for its powerful antioxidant, anti-inflammatory, and coloring properties. Widely used across nutraceuticals, functional foods, beverages, cosmetics, and pharmaceutical formulations, Blue Spirulina has gained global attention as a clean-label, plant-based ingredient.

India has rapidly emerged as a key hub for Blue Spirulina manufacturing, supported by favorable climatic conditions for spirulina cultivation, cost-efficient production, advanced extraction technologies, and strict quality compliance. Indian manufacturers now supply high-purity Blue Spirulina to both domestic and international markets, meeting the growing demand for natural and sustainable ingredients.

This page provides a comprehensive overview of leading Blue Spirulina manufacturers in India, highlighting top suppliers and exporters, production capabilities, quality standards, applications, and key factors buyers should consider when sourcing from India.

Blue Spirulina is a natural blue pigment-protein found in Spirulina platensis, a nutrient-rich blue-green microalgae. It belongs to the phycobiliprotein family and plays a vital role in photosynthesis by capturing light energy. Blue Spirulina is extracted from spirulina through water-based or advanced filtration processes, making it a clean-label, plant-derived ingredient suitable for food, nutraceutical, cosmetic, and pharmaceutical applications. Because it is non-toxic and biodegradable, Blue Spirulina is widely preferred over synthetic blue colorants.

Spirulina contains several natural pigments, each with distinct properties and applications:

Phycocyanin (Blue): Water-soluble pigment known for its antioxidant and anti-inflammatory properties. Commonly used as a natural blue colorant and bioactive compound.

Chlorophyll (Green): Fat-soluble pigment responsible for spirulina’s green color, mainly used for detoxification and oral care products.

Carotenoids (Yellow–Orange): Fat-soluble antioxidants such as beta-carotene, supporting eye and skin health.

Unlike chlorophyll and carotenoids, Blue Spirulina is both a functional ingredient and a natural colorant, making it highly versatile across multiple industries

Blue Spirulina is valued not only for its vibrant blue color but also for its health-supporting properties:

Powerful antioxidant that helps combat oxidative stress

Anti-inflammatory properties supporting immune health

Supports liver health and detoxification

May aid in cell protection and metabolic wellness

Nutraceuticals: Capsules, tablets, powders, and functional blends

Food & Beverages: Natural blue coloring for drinks, confectionery, dairy, and gummies

Cosmetics: Skin-soothing and anti-aging formulations

Pharmaceutical & Biotech: Research applications and therapeutic formulations

Due to its multifunctional nature, Blue Spirulina continues to see rising demand globally, positioning it as a high-value ingredient in natural and sustainable product development.

India has become a preferred destination for global buyers seeking reliable, high-quality Blue Spirulina suppliers. Several strategic advantages make India a strong manufacturing and export hub for this high-value spirulina extract.

India offers a significant cost advantage in Blue Spirulina manufacturing without compromising quality. Favorable climatic conditions reduce cultivation costs for spirulina, while efficient labor availability and locally sourced raw materials help keep production expenses competitive. These factors allow Indian manufacturers to offer cost-effective pricing for bulk orders, private labeling, and long-term supply contracts, making India attractive for global nutraceutical and food brands.

Leading Blue Spirulina manufacturers in India operate GMP, ISO, FSSAI, HACCP, and organic-certified facilities, ensuring consistent quality and safety. Advanced quality control protocols are followed at every stage—from spirulina cultivation and harvesting to extraction, purification, and final packaging. Strict testing for purity, Blue Spirulina content, heavy metals, microbial load, and contaminants ensures products meet international regulatory standards.

India’s well-established export ecosystem supports seamless global trade. Modern ports, efficient logistics networks, and experienced export documentation teams enable timely shipments to markets across North America, Europe, Asia, and the Middle East. Indian suppliers are familiar with international compliance requirements, including COA, MSDS, specification sheets, and country-specific regulations, making sourcing smooth for overseas buyers.

India has a strong pool of biotechnologists, food technologists, and pharmaceutical experts specializing in spirulina cultivation and Blue Spirulina extraction. Continuous R&D investments have led to improved extraction efficiency, higher purity grades, and better stability of Blue Spirulina for diverse applications. This technical expertise allows manufacturers to offer customized grades suitable for nutraceutical, food coloring, cosmetic, and pharmaceutical use.

Together, these advantages position India as a reliable, scalable, and globally competitive source for high-quality Blue Spirulina manufacturing.

India’s well-established export ecosystem supports seamless global trade. Modern ports, efficient logistics networks, and experienced export documentation teams enable timely shipments to markets across North America, Europe, Asia, and the Middle East. Indian suppliers are familiar with international compliance requirements, including COA, MSDS, specification sheets, and country-specific regulations, making sourcing smooth for overseas buyers.

India has a strong pool of biotechnologists, food technologists, and pharmaceutical experts specializing in spirulina cultivation and Blue Spirulina extraction. Continuous R&D investments have led to improved extraction efficiency, higher purity grades, and better stability of Blue Spirulina for diverse applications. This technical expertise allows manufacturers to offer customized grades suitable for nutraceutical, food coloring, cosmetic, and pharmaceutical use.

Together, these advantages position India as a reliable, scalable, and globally competitive source for high-quality Blue Spirulina manufacturing.

India’s Blue Spirulina industry benefits from diverse geographic regions that offer ideal conditions for spirulina cultivation and pigment extraction. From established hubs in the south and west to emerging production areas, these regions collectively strengthen India’s position as a global supplier.

Southern states such as Tamil Nadu, Karnataka, and Andhra Pradesh have become prominent centers for Blue Spirulina production. The region’s warm climate, abundant sunlight, and access to freshwater bodies provide optimal conditions for high-yield spirulina cultivation. Several well-established manufacturing facilities here focus on producing high-purity Blue Spirulina for nutraceuticals and food applications.

States like Maharashtra and Gujarat are recognized for large-scale Blue Spirulina production. These areas combine modern industrial infrastructure with cost-effective operations. Western India’s production centers often integrate advanced extraction and processing technologies, making them reliable suppliers for bulk exports and domestic markets alike.

While southern and western states dominate, Odisha, Telangana, and Rajasthan are emerging as noteworthy regions for Blue Spirulina cultivation. Investments in technology and small-scale spirulina farms in these states are helping meet the growing demand from both Indian and international buyers. These emerging regions are gradually expanding India’s capacity to produce high-quality Blue Spirulina at competitive prices.

Many production hubs are strategically located near major seaports such as Chennai, Mumbai, and Kandla, facilitating smooth logistics and global distribution. Easy access to ports allows manufacturers to efficiently export Blue Spirulina to markets in Europe, North America, and Asia, ensuring timely delivery and maintaining the pigment’s quality during transit.

Producing high-quality Blue Spirulina requires a careful, multi-step process that begins with spirulina cultivation and ends with rigorous quality testing. Here’s a breakdown of the typical manufacturing workflow followed by leading Blue Spirulina manufacturers in India:

The process begins with the controlled cultivation of spirulina, a blue-green microalga, in nutrient-rich water under optimal light and temperature conditions. Indian manufacturers often use open ponds or closed photobioreactors, depending on the scale and purity requirements. Proper cultivation ensures high biomass yield and maximal Blue Spirulina content, forming the foundation for a high-quality final product.

Once the spirulina biomass reaches the desired density, it undergoes cell disruption to release Blue Spirulina from within the algal cells. Techniques such as high-pressure homogenization, sonication, or enzymatic treatment are commonly employed. Following this, the pigment is extracted using water or mild buffers, ensuring that the Blue Spirulina remains stable and retains its natural color and bioactive properties.

The crude extract is then filtered to remove cell debris and other impurities. Advanced purification techniques, including ultrafiltration, microfiltration, or chromatography, are used to obtain high-purity Blue Spirulina. This step is critical for applications in pharmaceuticals, nutraceuticals, and food products, where color clarity and safety are paramount.

After purification, Blue Spirulina is concentrated and dried to produce a stable powder or liquid form. Spray drying, freeze drying, or vacuum drying methods are commonly used, preserving both the pigment’s color and bioactivity. The final product is then carefully packaged in moisture-proof, light-protective containers to maintain long-term stability.

Before being released for domestic or international markets, each batch undergoes rigorous quality control tests. Parameters such as purity, color intensity, microbial safety, heavy metal levels, and moisture content are thoroughly checked. This ensures that the Blue Spirulina meets both regulatory standards and buyer specifications, making Indian suppliers a trusted choice for global sourcing.

When sourcing Blue Spirulina from India, ensuring that manufacturers adhere to strict certifications and quality standards is essential. These certifications not only guarantee product safety and purity but also facilitate global export. Leading Blue Spirulina suppliers in India comply with the following standards:

1. FSSAI Compliance

All reputable manufacturers maintain compliance with the Food Safety and Standards Authority of India (FSSAI) regulations. This certification ensures that the Blue Spirulina produced is safe for consumption, meets hygiene standards, and is legally approved for the food and nutraceutical markets.

2. GMP (Good Manufacturing Practices)

Manufacturers following GMP guidelines maintain high standards in production processes, including cleanliness, equipment maintenance, and quality control. GMP-certified facilities ensure that each batch of Blue Spirulina is consistent in purity, potency, and safety.

3. ISO Quality Certifications

Many Indian suppliers hold ISO 9001 or related ISO certifications, reflecting their commitment to quality management systems. These certifications indicate standardized processes, traceability, and continual improvement in production practices.

4. Organic & Non-GMO Certifications

Blue Spirulina produced under organic and non-GMO standards is increasingly preferred by international buyers. Certifications from recognized organic bodies and non-GMO verifications confirm that the product is free from synthetic fertilizers, pesticides, and genetically modified organisms.

5. International Standards for Export

Top Indian Blue Spirulina manufacturers adhere to international export standards such as EU regulations, US FDA requirements, and HACCP guidelines. Compliance with these standards ensures smooth global distribution and acceptance in premium markets.

By choosing suppliers with these certifications, buyers can guarantee product authenticity, safety, and quality, reducing risks while sourcing Blue Spirulina for nutraceutical, food, cosmetic, or pharmaceutical applications.

Indian Blue Spirulina manufacturers offer a range of product forms to meet the diverse requirements of industries such as nutraceuticals, food and beverages, cosmetics, and pharmaceuticals. These variations ensure that buyers can select the most suitable form based on application, purity, and processing needs.

1. Powdered Blue Spirulina

Powdered Blue Spirulina is one of the most commonly produced forms. It offers ease of storage, longer shelf life, and simple incorporation into formulations. This form is ideal for dietary supplements, functional foods, and beverages where precise dosing and extended stability are essential. Indian manufacturers provide powdered Blue Spirulina in varying grades, including standard and high-purity variants.

2. Concentrated Liquid Extract

Liquid Blue Spirulina extracts are highly concentrated solutions that preserve the pigment’s bioactivity and antioxidant properties. This form is preferred in applications requiring quick dissolution, natural colorants for beverages, and cosmetic formulations. Many suppliers in India offer liquid extracts with controlled concentration levels tailored to industrial requirements.

3. High-Purity Food Grade

For applications in food, nutraceuticals, and beverages, manufacturers produce high-purity, food-grade Blue Spirulina. This grade ensures safety, regulatory compliance, and vibrant blue coloring without compromising on nutritional or functional benefits. Indian suppliers adhere to strict quality standards and certifications to meet global food-grade requirements.

4. Cosmetic Grade

Blue Spirulina is increasingly used in skincare and personal care products due to its antioxidant and anti-inflammatory properties. Cosmetic-grade Blue Spirulina is formulated to be gentle, stable, and compatible with creams, serums, and masks, offering natural blue pigmentation alongside bioactive benefits.

5. Custom Blends

Some Indian manufacturers also offer customized Blue Spirulina blends, combining different concentrations, grades, or complementary ingredients. This flexibility allows brands to create unique formulations tailored to specific product needs, such as enhanced stability, improved solubility, or targeted functional benefits.

By providing these varied forms, Indian Blue Spirulina manufacturers cater to a wide spectrum of industries, ensuring both versatility and quality for domestic and global buyers.

Blue Spirulina, with its vibrant blue color and potent bioactive properties, has become a versatile ingredient across multiple industries. Its natural origin, safety, and functional benefits make it ideal for a wide range of applications. Here’s how it is used across different sectors:

Blue Spirulina is widely incorporated into nutraceuticals due to its antioxidant and immune-boosting properties. It is commonly found in dietary supplements, capsules, powders, and tablets, supporting overall wellness and providing natural therapeutic benefits. Its role in reducing oxidative stress and inflammation makes it a preferred choice for health-focused consumers.

In the food and beverage industry, Blue Spirulina serves both as a natural ingredient and a functional additive. It is used in energy drinks, smoothies, protein powders, and functional snacks, offering not only vibrant color but also nutritional value. Its natural, plant-based origin aligns with the growing demand for clean-label and healthy products.

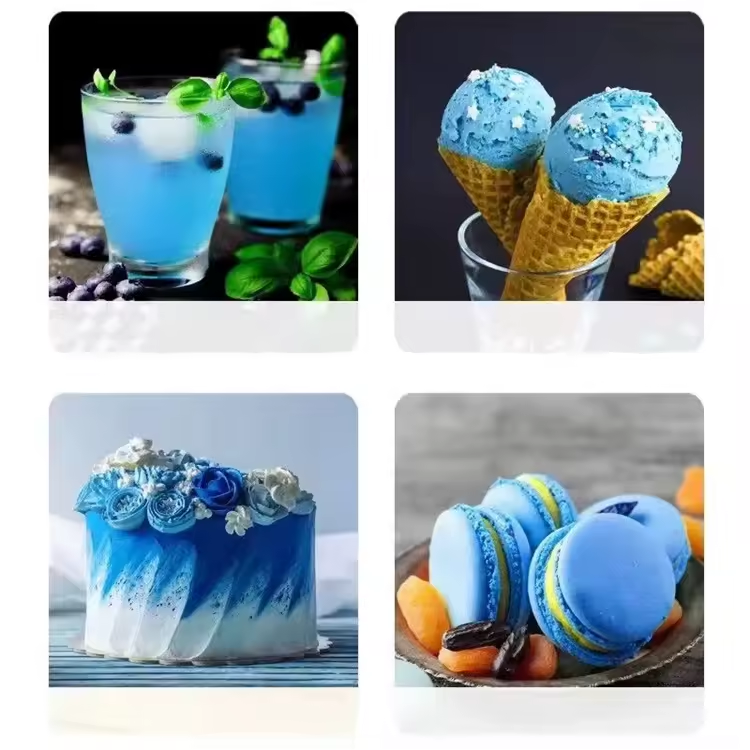

Blue Spirulina is an excellent natural blue colorant, replacing synthetic dyes in various products. It is extensively used in confectionery, ice creams, baked goods, dairy products, and beverages, providing bright blue hues without compromising safety or regulatory compliance. Its stability under controlled conditions makes it a reliable alternative to artificial colors.

Blue Spirulina is an excellent natural blue colorant, replacing synthetic dyes in various products. It is extensively used in confectionery, ice creams, baked goods, dairy products, and beverages, providing bright blue hues without compromising safety or regulatory compliance. Its stability under controlled conditions makes it a reliable alternative to artificial colors.

In the cosmetics and personal care industry, Blue Spirulina is valued for its antioxidant and anti-aging properties. It is used in creams, serums, masks, and lotions, helping to protect the skin from oxidative stress while providing a natural tint. Its bioactive compounds also contribute to soothing and rejuvenating effects in skincare formulations.

Blue Spirulina has shown therapeutic potential, including anti-inflammatory, immunomodulatory, and hepatoprotective effects. Pharmaceutical manufacturers are exploring its use in adjunct treatments, functional formulations, and clinical supplements, leveraging its natural bioactivity for preventive health and wellness.

Blue Spirulina is increasingly used in pet food and sports nutrition products. In pet food, it acts as a natural supplement to improve vitality and immunity. In sports nutrition, it supports energy, recovery, and antioxidant defense, making it a functional ingredient in protein shakes, energy bars, and performance supplements.

Indian Blue Spirulina manufacturers are not only focused on domestic demand but have also established a strong global presence, supplying high-quality spirulina-derived pigments to clients across multiple industries worldwide. Their export capabilities ensure that buyers receive products that meet international standards while maintaining consistency, purity, and safety.

Indian suppliers export Blue Spirulina to a wide range of countries, including the United States, European Union nations, Japan, South Korea, Australia, and the Middle East. These regions demand high-purity, certified Blue Spirulina for nutraceuticals, functional foods, beverages, cosmetics, and pharmaceutical applications. Manufacturers in India often cater to both bulk industrial orders and specialty formulations for international clients.

Exporting Blue Spirulina involves strict documentation and regulatory compliance. Leading Indian manufacturers provide all essential paperwork, including:

Certificates of Analysis (COA)

Material Safety Data Sheets (MSDS)

ISO, GMP, and HACCP certifications

Phytosanitary certificates (where applicable)

These documents ensure smooth customs clearance and compliance with international food, cosmetic, and pharmaceutical standards.

Proper packaging is crucial to preserve Blue Spirulina’s stability and potency during transit. Exporters in India use:

Food-grade, airtight containers to prevent moisture and light exposure

Vacuum-sealed or nitrogen-flushed pouches for bulk powders

Custom-labeled packaging to meet client branding and regulatory requirements

This approach guarantees that the product reaches overseas buyers in optimal condition.

Indian Blue Spirulina manufacturers collaborate with reliable freight forwarders to handle shipping efficiently. They offer:

Sea and air freight options depending on urgency and order size

Temperature-controlled shipping for sensitive batches

Real-time tracking for international shipments

Efficient logistics help ensure timely delivery while maintaining product integrity.

Export MOQs vary by manufacturer but typically range from 5 kg to 50 kg for bulk Blue Spirulina powder, depending on purity and client requirements. Many suppliers are flexible and can accommodate smaller trial shipments for first-time buyers, making India an accessible source for both large-scale distributors and niche international brands.

When sourcing Blue Spirulina from India, understanding the pricing and cost structure is essential for making informed decisions. Several factors determine the final cost, from product purity to packaging and order volume.

.

The price of Blue Spirulina can vary significantly depending on multiple factors:

Purity Level: Higher-purity Blue Spirulina (≥20–25% protein content or analytical grade) commands a premium price compared to lower-purity or food-grade variants.

Form: Blue Spirulina is available in powder and liquid forms, with extraction method and stability influencing costs.

Order Quantity: Bulk purchases typically benefit from economies of scale, reducing per-unit costs.

Extraction & Production Technology: Advanced extraction methods, such as freeze-drying or chromatography, increase product quality but also impact pricing.

Powdered Blue Spirulina: Generally more stable, longer shelf life, and easier for shipping. It is slightly more expensive due to the drying process and higher handling requirements.

Liquid Blue Spirulina: Offers faster application in beverages and formulations but has a shorter shelf life and requires cold storage, often making logistics costlier. On a per-gram basis, liquid Blue Spirulina can sometimes be cheaper for small volumes but may increase overall handling costs.

Indian manufacturers often provide tiered pricing for large orders. For example:

Small-scale orders (≤1 kg) may have standard rates.

Medium-scale orders (5–10 kg) can receive 5–10% discounts.

Large-scale orders (≥50 kg) can enjoy 15–25% price reductions, depending on purity and form.

These discounts make India a competitive sourcing destination for international buyers seeking high-quality Blue Spirulina at cost-effective rates.

Packaging plays a crucial role in both product stability and overall cost. Options include:

Food-grade foil pouches or jars for powders

HDPE bottles or aseptic containers for liquids

Premium packaging with airtight, UV-protective materials may slightly increase the price but ensures longer shelf life and safer transport.

Compared to North America, Europe, or East Asian suppliers, India offers significantly competitive pricing without compromising on quality. Cost savings are attributed to:

Lower labor and production costs

Abundant spirulina cultivation resources

Efficient export infrastructure

Overall, Indian Blue Spirulina manufacturers provide high-quality products at globally attractive rates, making India a preferred hub for both small-scale buyers and large international brands.

Leading Blue Spirulina manufacturers in India are increasingly adopting sustainable practices to minimize environmental impact while ensuring high-quality production. Sustainability is now a key focus, spanning water usage, energy consumption, waste management, and packaging innovations.

Efficient water management is critical in spirulina cultivation and Blue Spirulina extraction. Many manufacturers implement closed-loop water systems, enabling the reuse of water in multiple production cycles. Advanced filtration and treatment processes ensure that recycled water maintains quality standards while significantly reducing freshwater consumption.

Indian Blue Spirulina producers are investing in energy-efficient technologies, such as solar-powered pumps, LED lighting for cultivation tanks, and optimized drying systems. These initiatives reduce carbon footprints, lower operational costs, and support greener manufacturing practices aligned with global sustainability goals.

Sustainable spirulina farming is at the heart of eco-friendly Blue Spirulina production. Techniques such as organic nutrient inputs, minimal chemical usage, and controlled cultivation environments help maintain ecological balance. Some manufacturers also employ integrated aquaculture practices, combining spirulina cultivation with fish or algae systems to maximize resource efficiency.

Waste management is a priority for responsible manufacturers. Byproducts from Blue Spirulina extraction, like residual biomass, are often repurposed as animal feed, organic fertilizers, or bioenergy sources, ensuring zero-waste production cycles and contributing to circular economy practices.

To complement sustainable production, leading suppliers are adopting eco-friendly packaging solutions. Biodegradable containers, recyclable bottles, and minimal plastic usage reduce environmental impact and appeal to conscious global buyers seeking sustainable supply chains.

No. 15/11, First Floor, NSDR Nidhi Building, Rama Street, Nungambakkam, Chennai, Tamilnadu, India – 600034.

Algology. All Rights Reserved. Developed by Pixel Tech